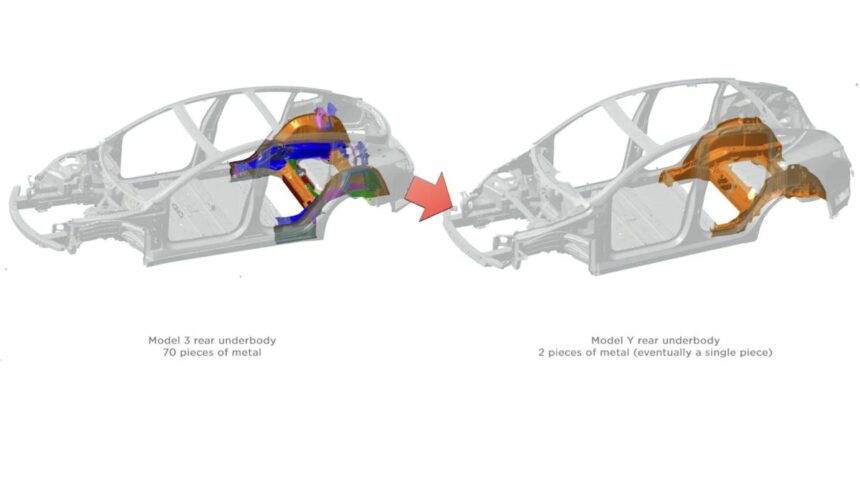

A technique known as gigacasting, which would have allowed Tesla to produce its cars’ underbodies in one piece, has been shelved, according to Reuters, which cited two people with knowledge of the development.

Newsng gathered that Tesla is attempting to adjust to a changing market environment with less sales and more competition by making this move.

Elon Musk had to go into ‘war CEO mode’ due to the first quarter’s poor sales, and Tesla had to start cutting expenses everywhere it could to stay competitive during a time of slowing demand.

The mass market Model 2 and the whole Supercharger team were among the projects and personnel that were let go, and it appears that Tesla has given up on its one-piece gigacasting dream.

This was meant to be the process that enabled them to cheaply create the Model 2. Tesla planned to press the entire chassis of its affordable car in one stroke, as opposed to having front and back gigacastings like on the Cybertruck or the Model Y.

Musk shifted the conversation to his favourite subject, autonomy, when questioned about Tesla’s gigacasting breakthroughs about its ambitions for more reasonably priced EVs and whether he was worried that his Chinese rivals might copy the method.

“We should be thought of as an AI robotics company,” he said. “If you value Tesla as just like an auto company… it’s just the wrong framework.”

Experts point to Tesla’s strategy shift to prioritising the development of self-driving capabilities above ambitious growth in EV sales.

As demand for electric vehicles declines, billionaire Elon Musk in an earlier report revealed intentions to lay off over 10% (or over 14,000 employees) of Tesla’s global staff.

Elon Musk made “the difficult decision” public in a note that was originally made public by the website Elektrek. 140,473 individuals work at Tesla, according to its annual report.